Centerless Grinding of molybdenum coated pin was tough as it clogged the wheels Challenges: Grinding Molybdenumcoated parts is tough as it clogs wheel An overused

Centerless Grinding of molybdenum coated pin was tough as it clogged the wheels Challenges: Grinding Molybdenumcoated parts is tough as it clogs wheel An overused

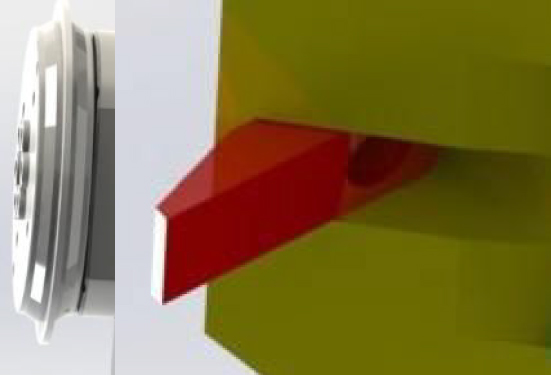

Objective: Rigid Tailstock, providing consistency in ground components output quality i.e. taper, cylindricity etc. Tailstock with Antifriction Guideways is designed suitably for MGT’s OD Grinding machines available

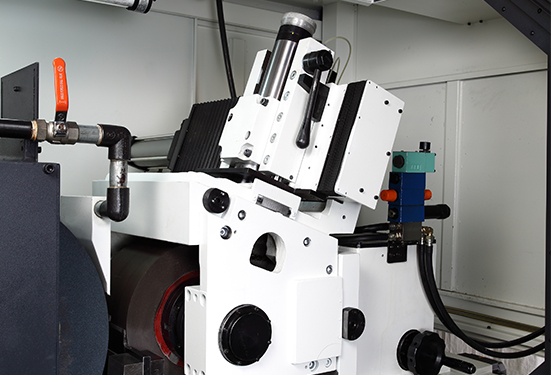

Rotary disc dresser This is a disc with diamond held in metal bond in multiplayer. The disc rotates at very high RPM for the

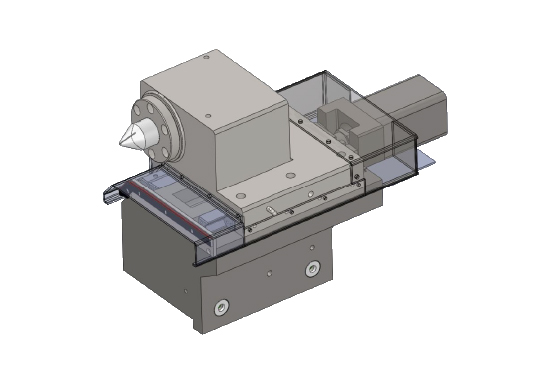

Production Grinding machines which run 24×7 require automatic load-unload system which are economical Challenge: Large production of medium weight parts e.g. automotive transmission shafts, etc.

MGT’s VAS team replaced the obsolete CNC system on the Centerless Grinder at customer’s end with minimum of downtime. CNC system replacement at Customer’s end in

Best Kaizens of the Year Awards for 2016-17 MGT has launched a new “Employee Recognition Program” under the title, “Best Kaizen’s of the year”

Caring the MGT way The best companies are those with happy employees. Companies today provide plentiful perks and a conducive work culture to motivate their

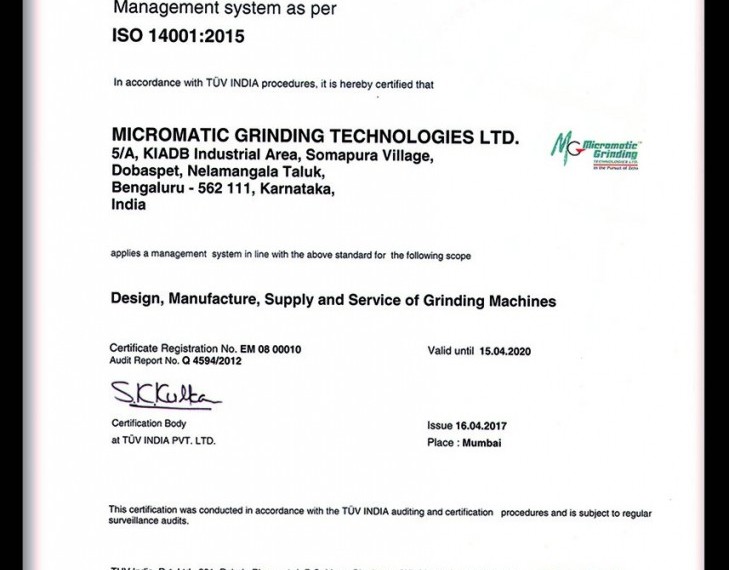

MGT’s BOTH PLANTS ARE NOW CERTIFIED WITH THE LATEST ISO 9001:2015 QMS by TUV-NORD Since its incorporation in 1973, MGT had always been following Quality Systems