Introducing MGT’s ‘Quick Wheel Change Arrangement’ to help you hasten your wheel replacement process and maximise machine uptime.

Micromatic Grinding’s new ‘Quick Wheel Change Arrangement’ to maximise machine uptime.

All grinding wheels require replacement after their diameter is reduced to the minimum recommended limit. This is a tedious chore that consumes 30-60 minutes of precious machine uptime leading to huge productivity losses. This becomes critical in cases where machines are running 24 x 7 and wheel replacement is carried out weekly or even more frequently.

To maximise machine uptime, MGT’s designers developed an indigenous solution by which you can now replace the worn-out wheel in 10 minutes or less.

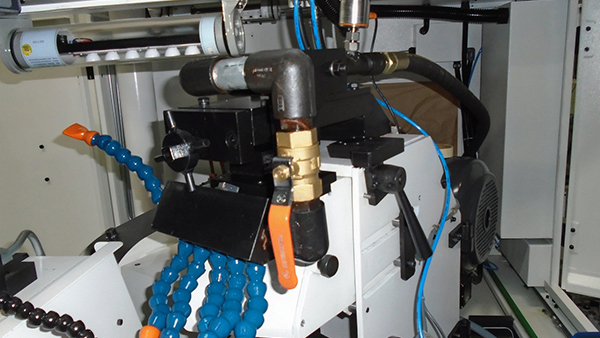

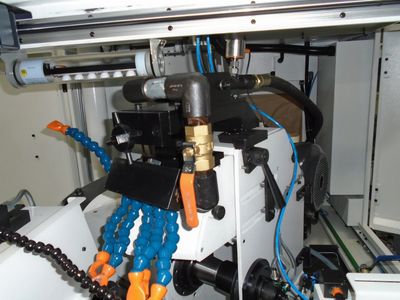

Introducing the ‘Quick Wheel Replacement Arrangement’ on the wheel guard. With the use of a cam lock and thumb screws for quick clamping and de-clamping of wheel guard cover, now there are 2 easy methods to remove the worn-out wheel, replace it with a new one, quickly place back the wheel guard cover and resume grinding.

Flapper With radial movement(option 1) |

Flapper with Linear movement(option 2) |

Method 1: Using the hand wheel at the rear side of the wheel guard for faster swing-up movement of the flapper to enable removal and replacement of the worn-out grinding wheel.

Method 2: By using the handle provided at the front side of the wheel guard with special lead screw for faster linear movement of flapper to remove and replace the worn-out grinding wheel.

We’d be glad to help you minimize your machine down-time woes due to grinding wheel change over. To know more about the ‘Quick Wheel Replacement Arrangement’ email us on [email protected]