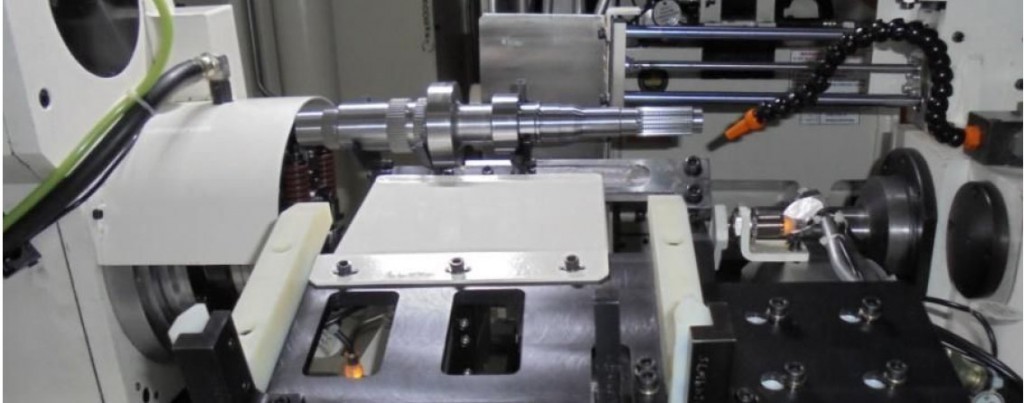

Production Grinding machines which run 24×7 require automatic load-unload system which are economical

Challenge:

Large production of medium weight parts e.g. automotive transmission shafts, etc. requires loading & unloading of the same on to the machine by the operator, approx. every minute, depending on the cycle time. This is very tiring & sometimes wrong loading causes serious accidents.

Typically, such grinding machines now run 24X7 these days & to maintain consistency in line output, respected supply chain vendors are demanding automatic loading-unloading systems on new machines. Such systems can be very costly, at times as much as additional 50% of the price of a new machine.

Challenge, therefore, is always to bring out an economic-cost effective Load-Unload system which doesn’t affect the overall grinding cost per part.

Benefits of the loader unit

• Low maintenance cost

• Economic cost automation

• Reduced component loading-unloading distance to minimize the operator fatigue

• One operator can tend to two machines simultaneously