Effective coolant management improves productivity, increases profits and lowers cost of consumables.

Increase productivity of grinding operations with better coolant management.

- Do your ground components have burn marks?

- Are you facing excessive wheel wear?

- Is reduced material removal rate increasing cycle time & lowering productivity?

- Does the same grinding wheel act softer or harder on the same components?

It’s time you pay heed to coolant management.

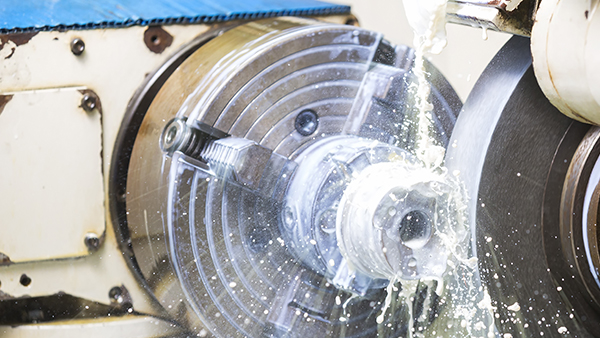

Grinding consumes three to five times more specific cutting energy than other types of machining operations to remove the same volume of material. During grinding a high percentage of process heat enters the component, which if not removed immediately with the effective use of coolant, could lead to undesirable re-hardening burn, thermal softening and tensile residual stresses, all of which affect component integrity.

|

The benefits of using coolant in a grinding process are multitude as it

-

- Removes heat from work zone

- Reduces the ill-effects of friction

- Increases the material removal rate

- Carries away grinding dust from the contact zone

- Helps in maintaining greater component integrity

- Enhances grinding wheel life

How can we make effective use of the all-important ‘coolant’ in the grinding process?

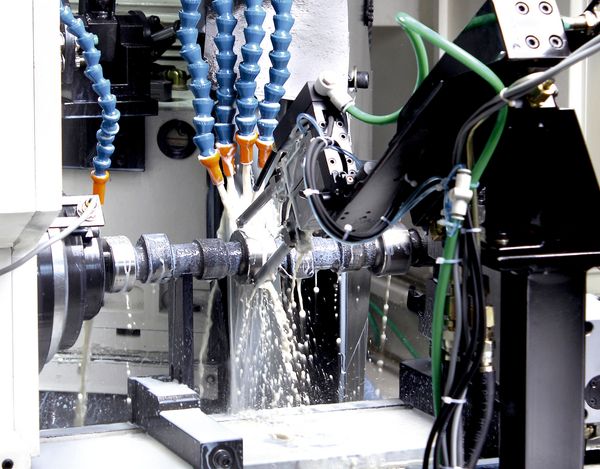

It is not about flooding the work area, instead it is about making sure that the coolant is delivered at the right place, at the correct flow rate and pressure, and by selecting the proper input conditions.And it doesn’t just end there. While using water-based coolants, it is important to understand how to prepare, store and periodically check the coolant. Few tips to consider,

-

- Use only the coolant recommended by the machine manufacturer

- Proportion of coolant to input water in the emulsion is of desired concentration

- Input water and resultant coolant emulsion conforms to recommended parameters as listed in Table 1 below

- Perform periodic checks to ensure that the critical parameters of the coolant emulsion are maintained as per the recommended values listed in Table 1 below

TABLE 1: Recommended critical parameters of ‘input water’ and ‘coolant emulsion’

| # | PARAMETER | INPUT WATER | RESULTANT COOLANT EMULSION |

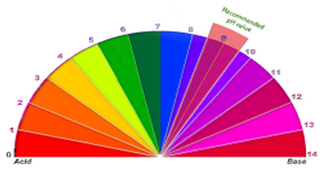

| 1 | pH | 6.5 – 7 | 8.5 – 9.5 |

| 2 | Hardness | < 200 PPM | < 550 – 600 PPM |

| 3 | Chloride content | < 25 PPM | < 50 PPM |

| 4 | Concentration | – | 3% – 5% by vol. of coolant concentrate to input water |

pH Scale |

Litmus Paper |

Refractometer (used to determine the concentration of the coolant) |

An effective coolant management process improves component quality, reduces the need for additional processes, prevents excessive rejects and increases overall productivity while reducing cost of consumables.